Home >What We Do >Design Guide

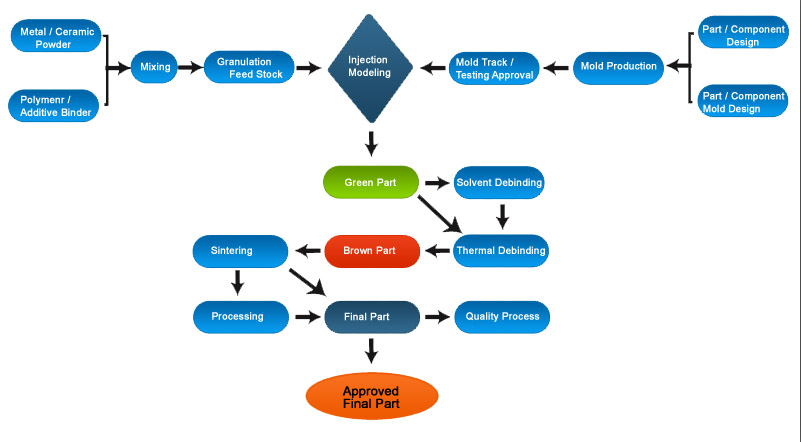

Metal Injection Molding (MIM) involves uniformly mixing solid powder with an organic binder. The mixture is then granulated and injected into a mold cavity using a heated injection molding machine, where it solidifies to form the molded part. The binder in the molded part is subsequently removed through chemical or thermal decomposition. Finally, the product is obtained by sintering and densification.

Compared to traditional processes, MIM offers several advantages, including high precision, uniform structure, excellent performance, and low production cost. Its applications span various industries such as electronic information engineering, biomedical equipment, office equipment, automobiles, machinery, hardware, sports equipment, clocks and watches, weapons, and aerospace.

Due to its potential to revolutionize parts forming and processing technology, MIM is often referred to as "today's hottest parts molding technology" and "the 21st-century forming technology."

Designing components for Metal Injection Molding (MIM) is similar to designing for plastic injection molding rather than other metal-forming processes. By disregarding the limitations of traditional metal-forming technologies, the design engineer has the freedom to reimagine a component from a fresh perspective. This thought process can consider reducing material content, consolidating multiple components into one, or incorporating functional and decorative features from the beginning.

To fully utilize the advantages of MIM in designing any part, whether it is a new design or a conversion from another manufacturing process, we provide a set of guidelines to improve its manufacturability. Additionally, this section includes information on secondary operations.

There is a huge list of applications, which make use of Metal Injection Mold parts and components. Here are some most common applications of Metal Injection Mold parts provided by Harber Metal:

1. Electronic Locks

2. Watches

3. Automotive

4. Electronic Industry Support

5. Shaft Assemblies

6. Spindle Housing Hubs

7. Valve Bodies

8. Suspension Arms

9. Rail and Switch Gear

10. Thermal Control

11. Fasteners

12. Medical Devices

13. Tensioners

14. Module Blocks

15. Ratchet Gears

16. Output Shafts

--MIM Metal Part should be designed to facilitate easy removal from the die. The sidewalls should be vertical; the hole axes should be parallel to the die opening and closing direction.

--Holes, even complex shapes, are possible in the compression direction. The smallest hole diameter is 1.5 mm (0.060 in).

--The wall thickness should be suitable for the process, typically 1.5 mm (0.060 in) minimum. The length to thickness ratio can be up to 18 maximum-this ensures that the tooling is strong. However, unlike other processes, the wall thicknesses can vary, which gives the designer more flexibility in designing the parts.

--Undercuts are not allowed, so designs have to be adjusted to avoid this limitation. Threads for screws cannot be formed and have to be machined later.

--Drafts are usually not needed except for recesses made by a punch creating a blind hole. In this case, a 2-degree draft is recommended. Note that the draft requirement is less strict than other forming processes such as casting, molding etc.

--Tolerances are 0.3 % on dimensions. If repressing is done, the tolerances can be as good as 0.1 %. Repressing, however, increases the product cost.

We understand that time is essential. Creating new products and solutions from scratch is great, but they have to be tested in real world scenarios. And they have to be tested fast. That's where Harber metal's capabilities are outstanding, and where we keep investing in our service. We collaborate with our customers from the start of the design cycle. From a preliminary idea we can prototype new designs at amazing speed – sometimes even within 24-hours – thanks to our highly qualified design engineers and our expertise.

| Material system | Alloy model | Application filed |

| Low alloy system | Fe2Ni, Fe8Ni | Structural parts in automobile, mechanical industries etc. |

| Stainless steel | 316L, 304, 17-4PH, 420, 440C | Medical devices, watch |

| Hard alloy | WC-Co | Various kinds of cutting tools, watches |

| Heavy alloy | W-Ni-Fe, W-Ni-Cu, W-Cu | Military, tele-communication |

| Titanium alloy | Ti, Ti6Al4V | Medical devices, military structural parts |

| Tool steel | CrMo4, M2 | All kind of tools |

| Material | Density | Hardness | Tensile strength | Elongation | |

| g/cm³ | Rockwell | Mpa | % | ||

| Iron base alloy | PIM-2200(sintering state) | 7.65 | 45HRB | 290 | 40 |

| PIM-2700(sintering state) | 7.65 | 69HRB | 440 | 26 | |

| PIM-4605(sintering state) | 7.62 | 62HRB | 415 | 15 | |

| PIM-4605(quenching, tempering) | 7.62 | 68HRB | 1655 | 2 | |

| Stainless steel | PIM-316L(sintering state) | 7.92 | 67HB | 520 | 50 |

| PIM-17-4PH(sintering state) | 7.50 | 27HRC | 900 | 6 | |

| PIM-17-4PH(sintering state) | 7.50 | 40HRC | 1185 | 6 | |

| PIM-430L | 7.50 | 65HRC | 415 | 25 | |

| Tungsten alloy | 95%W-Ni-Fe | 18.1 | 30 | 960 | 25 |

| 97%W-Ni-Fe | 18.5 | 30 | 940 | 15 | |

| Feature | Precision casting | MIM |

| Min hole diameter | 2mm | 0.4mm |

| Max depth for 2mm blind hole | 2mm | 20mm |

| Min wall thickness | 2mm | 0.3mm |

| Max wall thickness | No limit | 10mm |

| Tolerance for 4mm diameter | ±0.2mm | ±0.04 |

| Surface roughness(Ra) | 5μm | 1μm |

| Process Content | MIM | PM | Precision casting | CNC machining |

| Density | 90% | 86% | 98% | 100% |

| Tensile strength | high | Low | High | High |

| Finish | high | middle | Middle | high |

| Miniaturization capability | high | middle | Low | Middle |

| Thin all capability | high | middle | middle | Low |

| Complexity | high | Low | middle | High |

| Tolerance of design | high | Middle | middle | Middle |

| Material range | high | high | middle | high |

Metal powder injection molding is a versatile process that can produce complex metal parts for various industries, such as mechanical, electronic, automotive, office automation, watch, optoelectronic, military, medical devices and more.

Some examples of complex MIM parts applications are:

1) Computers and related devices: parts for printers, cores, striker pins, drive components and more.

2)Tools: such as gun drills, drill chucks, power tools, hand tools, wrenches and other spare parts, milling heads, nozzles and more.

3)Household appliances: such as watch cases, bracelets, electric toothbrushes, scissors, fans, golf heads, imitation jewelry, tool heads and more.

4)Medical equipment parts: dental orthodontic frames, orthopedic braces, scissors, tweezers and more.

5)Military ordnance parts: missile tails, firearms parts, warheads, liners, fuses and more.

6)Electrical parts: such as micro-motor parts, electronic parts, sensors, cell phones and more.

7)Mechanical Parts: complex parts such as small cotton gins, textile machines, sewing machines and more.

The metal injection machining process begins with experienced design engineers reviewing a part’s dimensions per customer drawing and then creating an AutoCAD rendition of the measurements in preparation for tooling. Our design engineer determines how many parts and offers suggestions of how the part can be manufactured with the lowest tolerances within our machining capabilities.

If your business is in need of a high quality and cost-effective metal injection molding service, then Mdm Metal have the solution to your problem.

Harber Metal is a China factory having a huge experience in the field of Metal Injection Molding services. For several years now, we have been serving clients from various industries, including aerospace, military, energy and electronics industries. We can provide custom prototype and MIM production machining and parts in diverse specifications. You can get in touch with our metal experts via phone on 86 0769-82389116. Alternatively, you can send us an email with your requirements and queries at sales@harber-mim.com.

Send A Message

Send A MessageIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.