Home >What We Do > What are the benefits of metal injection molding?

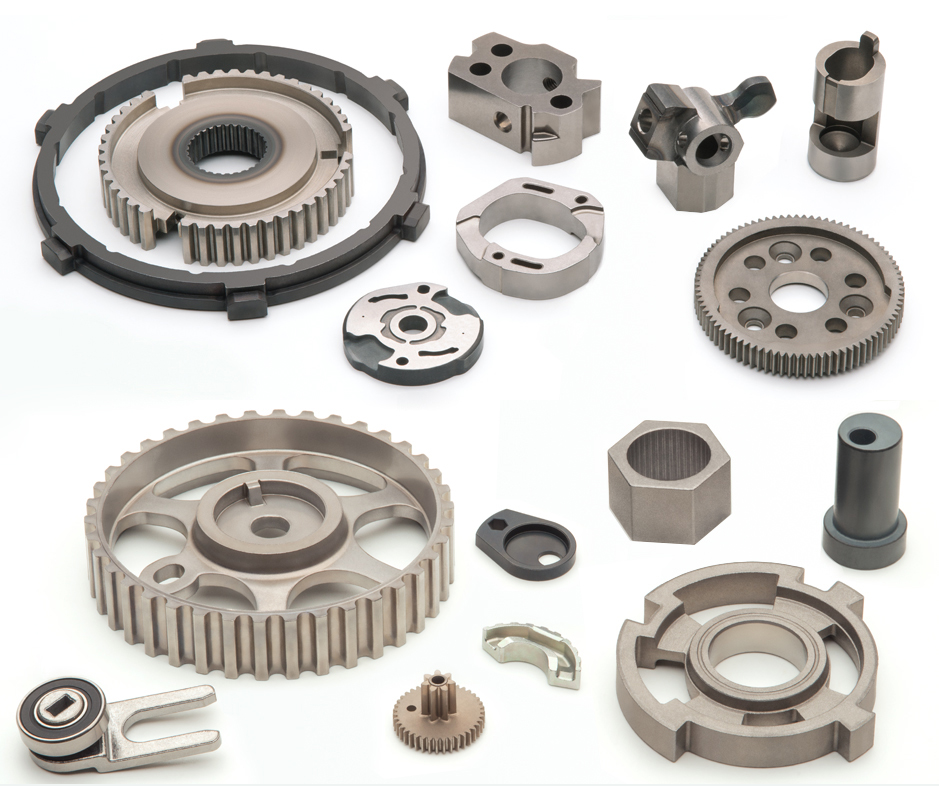

Metal injection molding is commonly used to produce parts of varying complexity such as complex internal structures, intricate shapes, small or tiny components, and components with fine features.

1. Cost Savings: Metal injection molding (MIM) offers high complexity for small components by utilizing near-net shaping and molding with powdered metals. This leads to cost savings since the production of small components and assemblies requires only one process cycle.

2. Design Flexibility: MIM offers greater design flexibility than casting and machining, allowing for the production of complex geometries with a variety of materials.

3. Weight Reduction: Complex and intricate shapes produced through MIM can lead to greater component lightness when compared to traditional machined or casted parts, making them ideal for aerospace, automotive, and other applications.

4. Improved Finish Quality: MIM offers a much higher surface finish than conventional processes, resulting in fewer part defects due to machining errors.

5. Excellent Reproducibility: The uniformity in mold cavities and increased precision in component sizes and tolerances can provide repeatable, reliable products that require less post-treatment.

6. Performance Enhancement: Various additives can provide a variety of enhancements to the overall properties of your component, such as higher strength, improved corrosion resistance, and improved wear properties.

Manufacturers are always looking for an advantage in quality, cost, and production time – all to provide better services and product options for their target markets. As a result, they often compare side to side but look outside the box when they crave innovation or a more cost-effective solution for their manufacturing needs.

Previous: The Cholice of MIM Tools Material

Next: 无

Send A Message

Send A MessageIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.