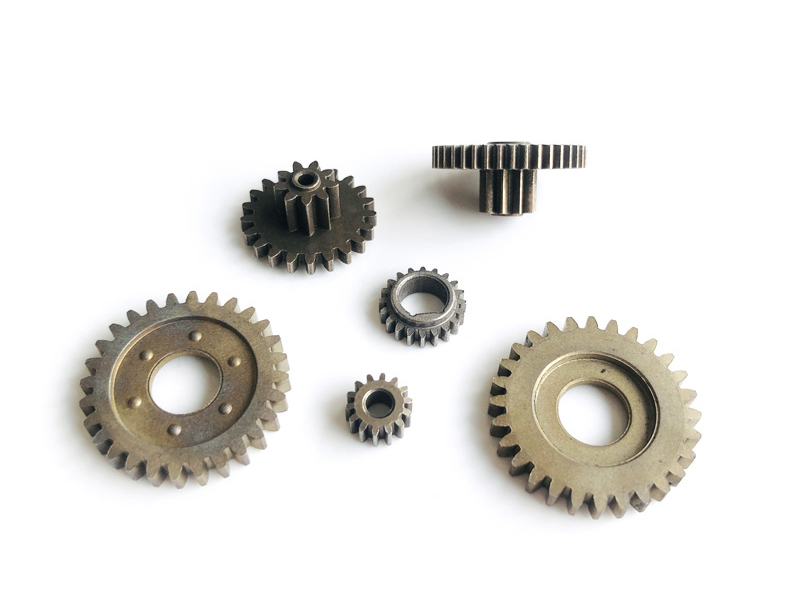

Home >Metal Products >MIM Products > MIM Factory Metal Injection Molding Gear Parts

Product Description

Metal injection molded gears and other precision mechanical components are some of the most successful MIM parts with a unique combination of cost and performance. MIM hardware is increasingly utilized in automotive, consumer, military and medical products.

Performance

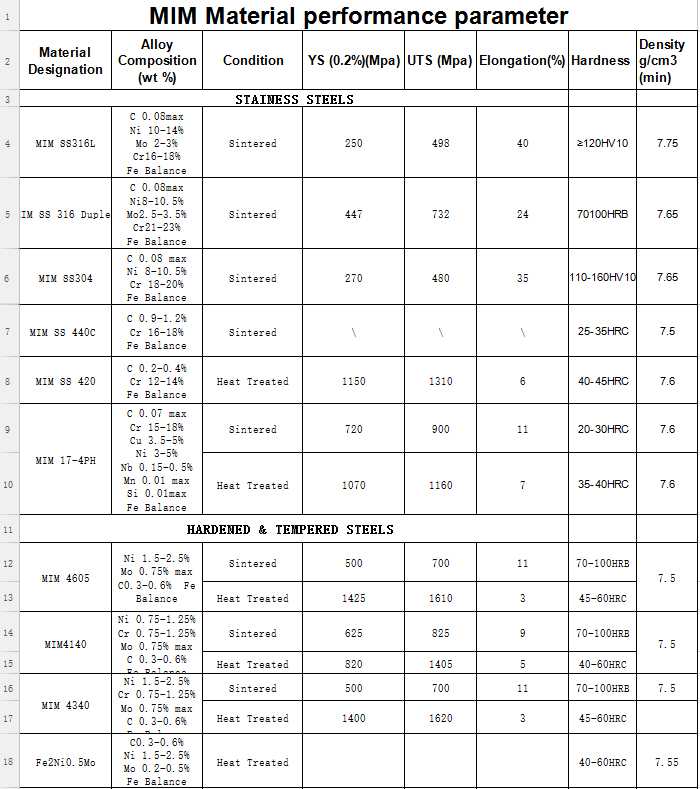

A variety of MIM alloys have been developed to meet toughness, corrosion resistance and hardness requirements.

Typical Materials

316L Stainless Steel

17-4PH Stainless Steel

Fe-2%Ni – Nickel Steel

Fe-8%Ni – Nickel Steel

Fe-50%Ni – Iron-Nickel

Engineered for Maximum Value

MIM technology provides the unique ability to produce highly complex components that cannot be achieved economically by any other process.

Harber Industrial works closely with you on design, materials and finish requirements to extract maximum value from the MIM process. Our extensive in-house capabilities in machining, heat-treating and surface finishing provide a way to manage total program cost.

Powder Injection Molding (PIM), which encompasses Metal Injection Molding (MIM) ), is a new type manufacture technology which combines plastic injection molding process with powder metallurgy process. It is a net-shape process for the manufacturing of high volume high precision components for use in a diverse range of industries. MIM parts can now be found in all areas of life, from our cars and trucks to watches, dental braces, mobile phones, IT equipment, DIY tools and much more.

Adaptable Production Demands

The wide range of applications for industrial products demands a supplier who is capable of meeting both small and large batch-manufacturing requirements.

Brand name | OEM & ODM |

Product type | Lock Parts |

Product Model | HBMIM-001B |

Material | Stainless steel 304,316L,17-4PH,TI |

Post-Sintering | Polishing,Wire-drawing,Sandblasting,Plating,Coated,etc. |

Size | Custom |

Tolerance | 10mm±(0.02-0.04)mm |

Weight | ≤200g |

Forming Method | Metal Injection Molding |

Sintering method | Solid phase sintering |

Sintering environment | Vacuum |

Mold material | Steel |

Application | Lock industry |

Shape | Custom |

OEM | Accept |

QC system | 100% inspection before shipment |

Payment terms | T/T at sight, Paypal, Western Union,etc. |

Lead time | 25-30 working days |

Supply capability | 500000 Piece Per Month |

Packaging | PP bag / Anti-static film / anti-static plastic disc |

Materials for Diverse Applications

We provides a wealth of material options that allow our customers to achieve high performance in their products.

MIM Industrial Product Solutions

Door hardware – Lock housings, cylinders, carriers, pins

Hand and power tools – Handles, bits, keyless chucks, blade clamps, pawls, ratchet mechanisms

Electronics – Sensor housings, fiber optic connectors, microwave packages, heatsinks

Hydraulics – Valve spools, housings, lavatory fixtures

Fasteners and Hardware – Aerospace

Plumbing – Valve spools, faucet hardware

Safety – Fall protection mechanisms

Oil & Gas – Valve components for high corrosion applications

Products Range:

| MIM Processing | Molding, Injection, Debindin

|